The Project

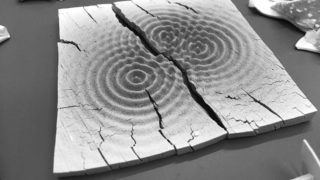

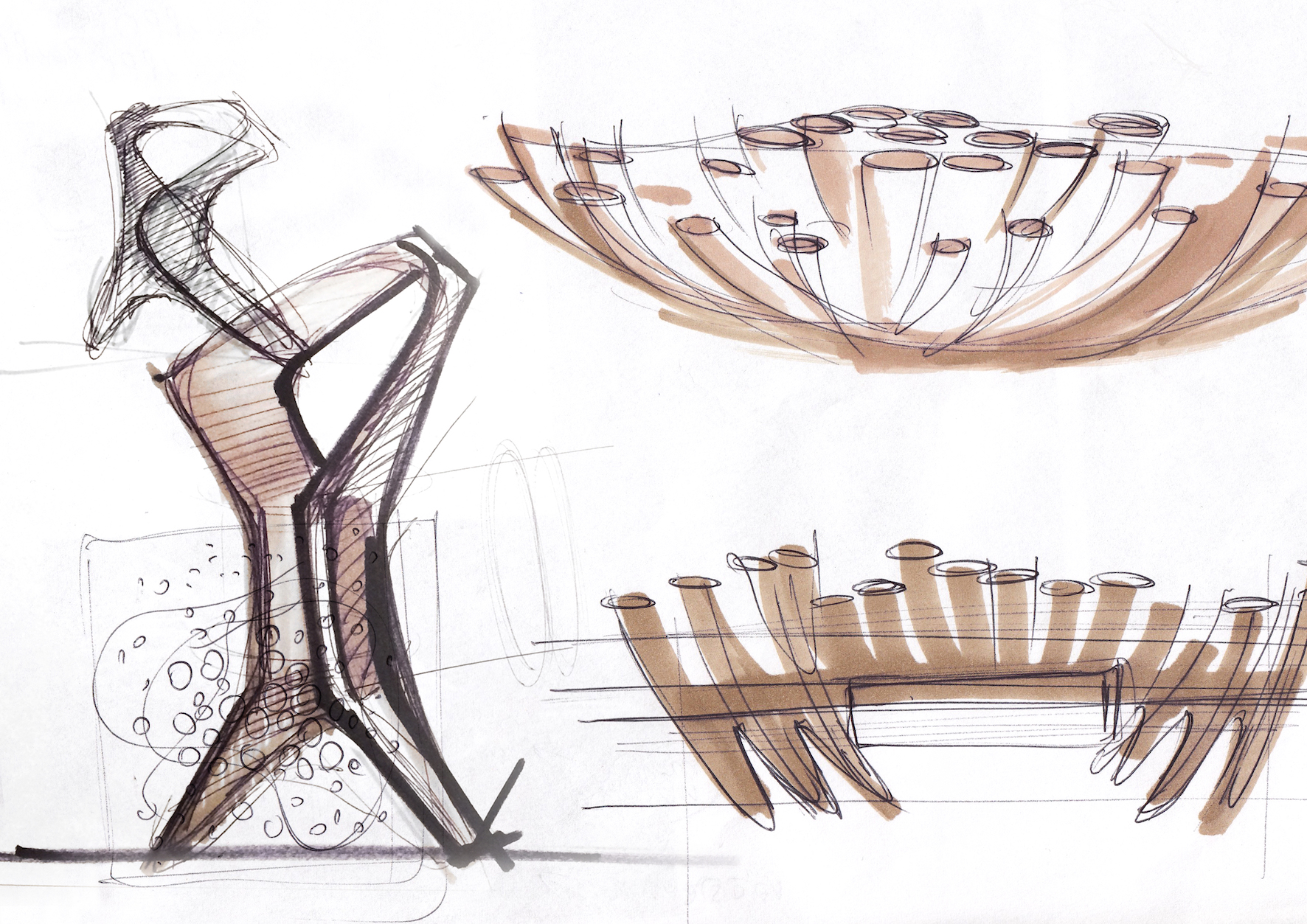

The goal of the project is to launch a new brand of 3D printed, on demand homeware called “CLAY NEXT”, bringing together consumer electronics, digital fabrication tools and local craft production. Thanks to an excellent product design and a careful market analysis, CLAY NEXT aims to link traditional ceramics to contemporary life and modern aesthetics. The project hopes to disrupt the image of traditional ceramic-making and bring back “Made in Slovakia” crafts products. Low volume 3D printing production not only allows for mass customisation of products, but also for freedom of shape, high resolution details and, most importantly, an effective use of materials.

The Partners

Manufacturer: TVAROCH, s.r.o.

Founded by industrial designer Matej Korytár, TVAR Open Creative Hub brings ideas to reality. As one of the few rapid prototyping studios based in Bratislava, since 2013 TVARoch specialises in additive manufacturing. The studio covers the whole process of design, prototyping and manufacturing of both industrial components and consumer products in small series, offering a wide range of production technologies and materials. Beside high quality and fast 3D printing technologies (SLA, SLS, FDM and binder jetting), the company provides production services in the field of CNC milling, casting and laser cutting as well as consultancy services such as feasibility studies.

Maker: Michala Lipková

Maker: Michala Lipková

Michala Lipková, ArtD. is a product designer active in the Bratislava’s start-up scene, working along the boundaries of physical and digital product design and UX. In 2016, she has defended her doctoral degree dissertation project “Craft for 21st century“ (crafts.sk), focused on the intersections of traditional craft making and the latest tools of digital fabrication. Beside her commercial work, she is an Assistant Professor at the Institute of Design at the Faculty of Architecture (Slovak University of Technology in Bratislava), where she mainly leads commissioned research projects for the automotive industry. Since 2012, she has been managing the NGO Flowers for Slovakia. In 2015 Michala has co-founded hardware startup Benjamin button. The project was awarded at the Slovak Startup Awards and successfully funded on Kickstarter.

Maker: Tomáš Tholt

Maker: Tomáš Tholt

Ing. arch. Tomáš Tholt is a PhD candidate at the Institute of public buildings at the Faculty of Architecture (Slovak University of Technology in Bratislava). During his studies, Tomáš took part in several national and international competitions and workshops. His doctoral degree research is focused on the phenomena of emergence, behaviour simulation and conscious complex systems in the design and fabrication process in the disciplines of architecture, design and spatial art. He has extensive experience in leading digital fabrication and software courses exploring the creative use of tools of generative design and emergent fabrication. Since 2015, Tomáš collaborates with rese_arch, a NGO established in 2009 to support architectural theory and education in Central Europe. Beside his research activities, Tomáš works as a freelancer mostly in the field of architecture, generative and multimedia design.

#MeetTheChampion

How did you get involved in the OpenMaker project?

The feasibility study of the project (material research) was already supported by the grant scheme “Viac dizajnu” of the Tatrabanka Foundation. We then identified the OpenMaker project as the ideal opportunity to further develop our vision!

What are the main strengths and challenges of your maker-manufacturer partnership?

The unique added value of the partnership is the combination of our previous experiences and teamwork, as well as our diverse background and complementary expertise - this allows us to contribute to the project on different levels. The partners have a strong track record in projects related to product research and prototyping. The main challenge that we face right now is the integration of the final craft process and its influence on the final product design.

Dream big! What would be the greatest achievement for your project?

We want to strengthen the local collaborative ecosystem - the project connects 3 partners with very different expertise (digital fabrication + product design + generative design) and the end result is pave the way to more collaborative initiatives through manual craft processes. It’s a rare combination that hasn’t successfully been put into commercial practice in our country yet. The critical challenge that the project aims to resolve is to create a sustainable business model based on the unique combination of the latest fabrication technology and traditional crafting, through on-demand production possibilities.

What do you hope to get out of the OpenMaker experience?

We are grateful for the opportunity to push the project to the next stage. Our ambition is to start the production and sale of the new brand’s very first product(or product line) of household wireless chargers for mobile phones and wearable devices, made from 3D printed ceramics and hand finished through the traditional process of firing and glazing. Our unique selling point will be innovative aesthetics, product customisation and the social aspect of the project by sustaining local tradition. The main focus is to develop in-house processes and software solutions (based on generative design) for custom on-demand design and production. We want CLAY NEXT to become the first Slovak brand that makes the most of decentralised forms of production, a brand capable of producing truly mass customised while supporting local ceramic makers.